Net Zero Energy Homes

Can remodels reach zero energy?

By Steve Russell

A recent post on NARI’s blog noted that “94% of remodelers are involved in one or more types of energy savings upgrades,” based on a survey of 621 NARI members. These upgrades ranged from duct insulation to high efficiency furnaces. The number one upgrade? Insulating the building envelope.

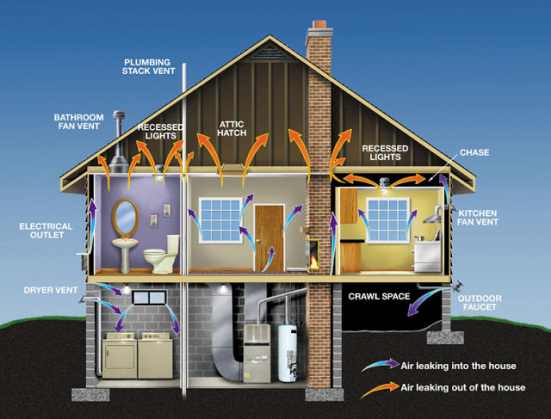

As it should be. Energy efficiency upgrades that bypass insulating and sealing the building envelope can contribute somewhat to energy savings, but even the most efficient HVAC system will still be wasting energy (and money) if the house is poorly insulated and leaky.

Net Zero Energy Homes

This is most certainly true when building or remodeling homes to achieve “net zero energy .” This type of home sometimes uses energy from the power grid and other times gives some back. In the end, the give and take balance out, and the homeowners’ energy consumption nets out at zero.

.” This type of home sometimes uses energy from the power grid and other times gives some back. In the end, the give and take balance out, and the homeowners’ energy consumption nets out at zero.

These homes typically have two things in common:

- a passive energy source, such as solar and geothermal, plus

- a building envelope that dramatically improves energy efficiency (compared to typical homes) by using modern insulation systems that increase R-value and by eliminating unintended air infiltration.

To demonstrate and publicize zero energy technologies and opportunities, the National Institute of Standards and Technology (NIST) built a “Net Zero Energy Residential Test Facility” near Washington, DC, in 2013. On its one-year anniversary, NIST announced that the home had produced more energy than it used, enough to “power an electric car for about 1,440 miles.”

Here’s what a NIST engineer said about the building envelope: “The most important difference between this home and a Maryland code-compliant home is the improvement in the thermal envelope – the insulation and air barrier. By nearly eliminating the unintended air infiltration and doubling the insulation level in the walls and roof, the heating and cooling load was decreased dramatically.”

Net Zero Energy Remodels?

OK, so some new homes can reach zero energy. Can remodels reach zero energy? Yes, with the right materials. Just how do we get there? To borrow a famous line from a movie: I’ve got one word for you. Plastics. As Mr. Robinson declared, there was a big future in plastics back in the 1960s. And there still is, particularly as the zero energy trend grows.

OK, so some new homes can reach zero energy. Can remodels reach zero energy? Yes, with the right materials. Just how do we get there? To borrow a famous line from a movie: I’ve got one word for you. Plastics. As Mr. Robinson declared, there was a big future in plastics back in the 1960s. And there still is, particularly as the zero energy trend grows.

While each building is unique and use many energy efficiency techniques, zero energy homes typically rely on modern plastic foam insulation products under and around the foundation, in the walls, and in the roofing. These products can increase R-value and reduce leaks and air loss to seal the building envelope, dramatically decreasing the amount of energy needed to heat and cool a home.

We’re not talking novel or newfangled insulation systems – they all are currently available to homebuilders and remodelers. Such as…

Building Products That Help Reach Net Zero

- Sheets of polystyrene foam around the home’s foundation (and under additions) create a barrier and insulate the floors and walls.

- When creating/replacing walls, insulated concrete forms – usually expanded polystyrene forms that stack and are filled with concrete and rebar – can provide excellent insulating properties and create a very solid building.

- Another advanced wall system, structural insulated panels, typically sandwich large sheets of expanded polystyrene foam between oriented strand board (OSB), creating large wall systems with few seams, high R-value, and improved strength.

- Polyiso or polyurethane foam, installed under the roof system instead of in the attic floor, help seal the building against leaks and increase the R-value of the roofing system. The NIST home used this method to achieve an R-value of 75 in its roofing system, which is about twice the typical R-value of area homes. In addition, because the attic is tempered space, ductwork doesn’t shed its cool or hot air in un-tempered space.

- The NIST building used six-inch instead of four-inch studs in order to increase the space for insulation between studs, plus a plastic air moisture barrier and four inches of polyiso foam on the exterior, which virtually eliminated thermal bridging.

- Plastic house wrap can significantly diminishes the infiltration of outside air, helping to reduce the energy required to heat or cool the home.

- Many other building envelope products – insulated window frames clad in plastics, “warm edge” plastic spacers between window panes that reduce thermal bridging and the potential for insulating gas to leak, plastic window films that reflect unwanted light/heat, doors insulated with plastic foam – also help improve energy efficiency.

- To seal the home and reduce leaks, plastic sealants (caulks, mastics, foams, tape, aerosols) can be used to close remaining gaps that may exist between floors, walls, roofs, and windows, as well as around ductwork joints.

Many other energy saving products made with plastics typically are used, such as plastic piping for radiant heat and efficient water delivery, highly insulated and energy efficient refrigerators, and even new solar roofing tiles made with plastics. And like the insulation systems, all of these building products are readily available and in use right now.

Investing in the Future

Granted, some of these upgrades may cost a bit more than traditional materials, but the return on investment usually can be measured fairly easily: incremental remodeling costs divided by the annual savings of an energy bill that equals zero. In the NIST example above, it is estimated that the homeowners would save $4,400 per year in heating, cooling, and other electricity costs.

Remodeling to reach zero energy soon may become commonplace. California already requires that all newly constructed homes be net-zero energy ready by 2020. Can similar requirements for remodeling be so far behind?

As Vice President of American Chemistry Council’s Plastics Department, Steve Russell is responsible for promoting the benefits and innovations of plastics to consumers, policy makers, and in key end use markets. Working with CEOs and member company executives, he leads the development and implementation of proactive programs and partnerships to promote sustainable solutions, and works with stakeholders to address unwarranted bans/taxes of plastic products. Visit Plastics Make It Possible for more information.

As Vice President of American Chemistry Council’s Plastics Department, Steve Russell is responsible for promoting the benefits and innovations of plastics to consumers, policy makers, and in key end use markets. Working with CEOs and member company executives, he leads the development and implementation of proactive programs and partnerships to promote sustainable solutions, and works with stakeholders to address unwarranted bans/taxes of plastic products. Visit Plastics Make It Possible for more information.

| 3/24/2015 12:00:00 AM |

2 comments